Manufacturing Process Introduction

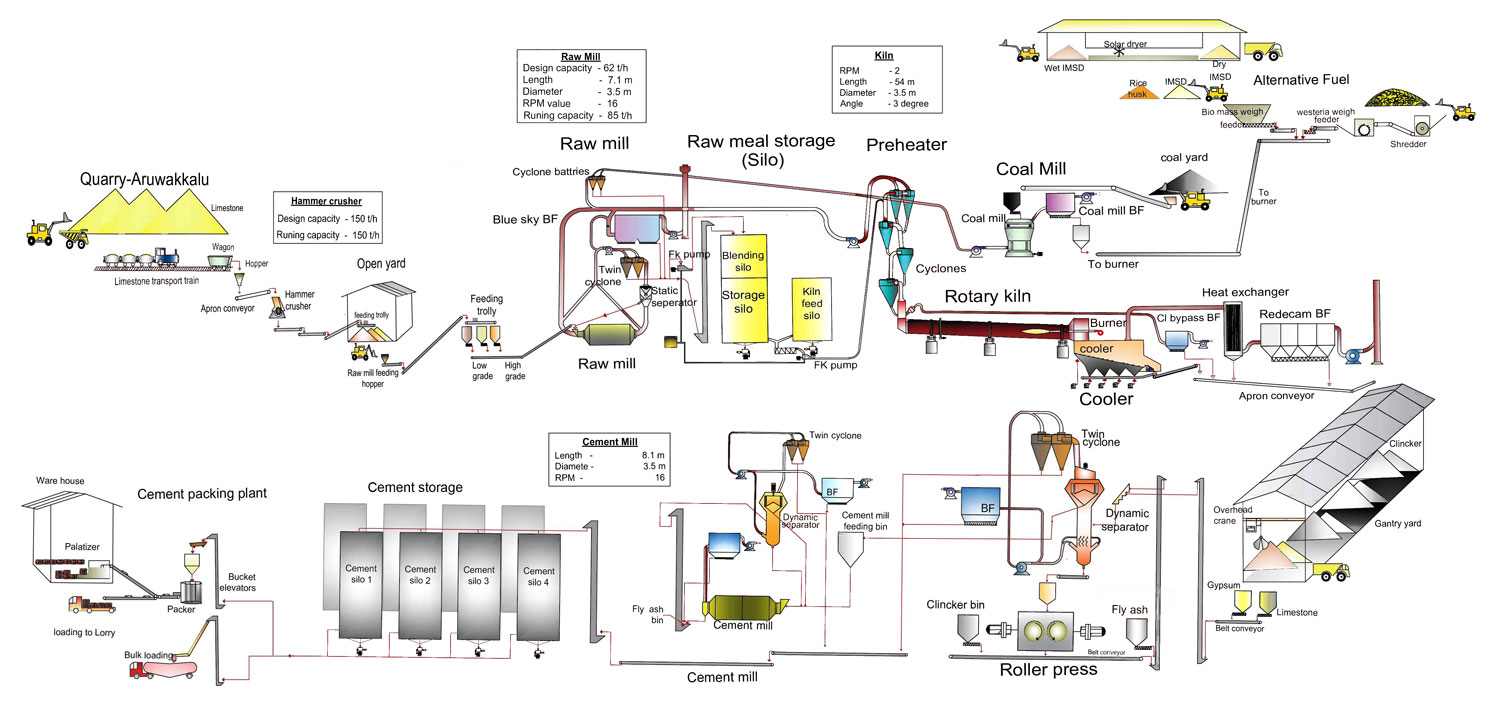

The cement manufacturing process consists of the following stages as explained in the following flow chart

The cement manufacturing process consists of the following stages as explained in the following flow chart

The main raw material required for cement manufacturing is limestone extracted from 40km away from the Puttalam plant.

Extracted limestone is transported to the plant by railway wagons for crushing. The limestone is initially fed into a primary hopper from which limestone boulders are fed to the crusher (impact hammer crusher) through a material conveyor. The crushed limestone pieces are discharged through the screen and are transported by belt conveyors to the stacking and storage yard.

Limestone from the crusher is transported to the storage yard by belt conveyors. In order to increase the uniformity of the material, limestone is being stacked in a heap with one layer on top of the other. Limestone is retrieved as a cross-section from the stockpile to reduce material variation. The main goal of pre-blending raw materials is to evenly distribute heat during the pyro operation. This helps reduce variations in the quality of the final product and improves energy efficiency.

In addition to raw material (limestone), minor additives are fed to the system to correct silica, alumina, and iron oxides in the raw material mixture. This additive is mainly made up of laterite. Other minerals such as slag, industrial sludge, and bottom ash are also used in minor quantities.

Limestone and additive (laterite) are placed in the feeding hoppers from the storage yard. Raw materials are ground using ball mills, which are rotating drum-shaped chambers with durable liners inside. The exhaust gas from the kiln serves as an energy source for drying the materials during grinding and as a carrier gas for transporting the ground material.

The pulverised raw material is called raw meal. This is then transported to the raw material silo after it is separated by a classifier.

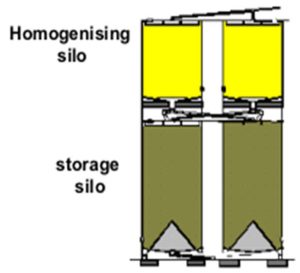

After this, the materials are homogenised using the air that is blowing inside the silo. This gives the material a fluidised motion.

This operation lasts 32 minutes.

The homogenised material mixture is then sent to the storage silo at the bottom of the raw mill silo.

The material from the storage silo is extracted, and fed to the weighing hopper through air slides and bucket elevators. The material flow to the weighing hopper is controlled with a variable speed rotary feeder. The material from the weighing hopper is directed to an electronic weigh feeder and transported to the top of a preheater using air slides, belt bucket elevators, or pneumatic pumps

The pyro operation goes through four stages of cyclone separators and then a rotary kiln. There are two cyclones utilised in stage 01 while a single cyclone is used in stages 02,03 and 04. The discharge stream of the 4th cyclone is directed to the rotary kiln, followed by a clinker cooler. The rotary kiln is a hollow cylindrical tube with protective lining inside to protect it from high temperatures. The cooler, which is operated by grates, is connected to the discharge end of the kiln.

Raw meal from the storage silo is first fed to the top stage of the cyclone and transported to the other stages via pneumatic transport. The geometry of the cyclone, along with pneumatic air transport, allows the raw material to absorb heat from the gas which then triggers various physical and chemical reactions.

Coal is the main energy source for the pyro processing. Raw coal is finely ground and then stored in a silo and fed to kilns through pneumatic transport which helps the flame to spread. The burner is placed along the kiln axis, opposite to the direction of the material and exhaust air flow. The flame's temperature reaches about 2000 degrees Celsius, heating the material to around 1450 degrees Celsius.

The temperature of the raw material starts off at around 90 degrees Celsius. This will increase to 850 degrees Celcius when it reaches the kiln after passing through the cyclone stages. As the kiln rotates, the material gradually travels towards the outlet. The feed enters the kiln at 850 degrees Celsius and needs to be heated up to 1450 degrees Celsius in the burning zone to produce c3s (alite), the main mineral component of clinker. As the material moves through the kiln, it undergoes calcination, releasing carbon dioxide (CO2) and forming calcium oxide (CaO). The primary oxide in the process, CaO, reacts with other oxides such as silica, alumina, and iron oxide present in the raw meal at high temperatures, resulting in the formation of clinker compounds: di-calcium silicate or belite (c2s), tri-calcium silicate or alite (c3s), tri-calcium aluminate or aluminate (c3a), and tetra calcium alumino-ferrite (c4af). This process, taking place in the preheater and kiln, is known as calcination and mineralization, leading to the production of clinker.

Once Alite is formed at a temperature of 1450 degrees Celcius, it needs to be rapidly cooled down so that the mineral structure of clinker is retained. The hot clinker from the kiln is cooled by air in the grate cooler. Inside the cooler, there are a number of fixed and movable rows of plates with air flow nozzles. The air is blown through the nozzles of the cooler plates, and cools the hot clinker that flows over the plates. The air is provided by five cooler fans operating centrifugally. The cooler plates move, pushing the clinker to the discharge end. The cooled clinker is then discharged to an apron conveyor. Part of the air used to cool the clinker is absorbed into the kiln as secondary air used in the burning operation. The remaining excess air is taken in by a cooler ID fan through a heat exchanger and a bag filter.

Manufactured clinker is stored in the clinker yard for cement grinding.

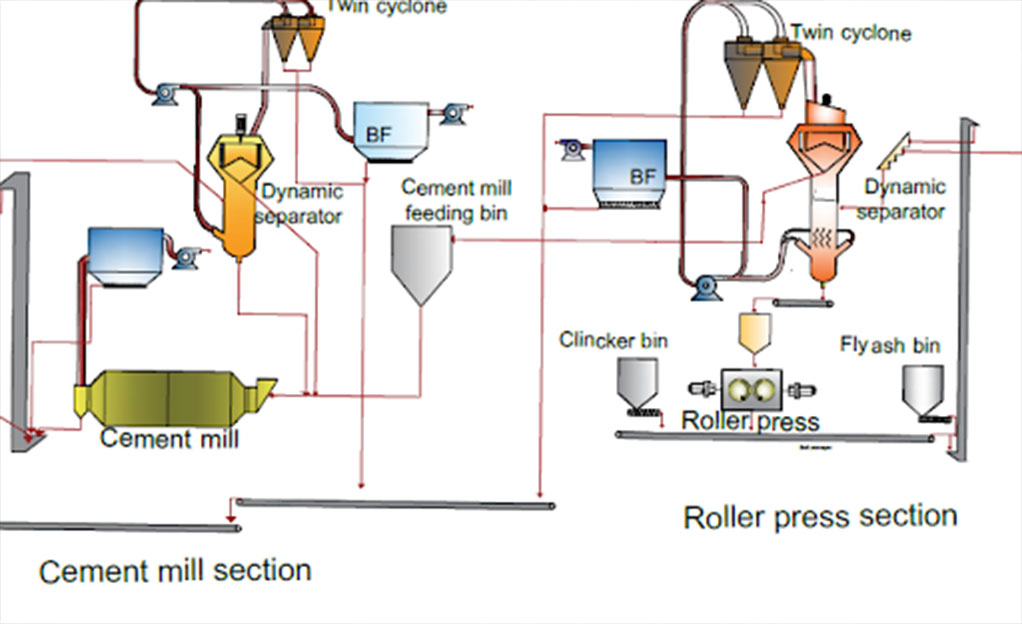

Clinker stored in the clinker yard is fed to a roller press unit along with a combination of gypsum and a mineral component mixture (MIC). This MIC is a combination of limestone and fly ash and the proportions of each depend on what type of cement needs to be produced. Once the material is fed into the roller press unit, some of the larger particles are moved to horizontal ball mills called cement mills. The roller press acts as a pre-grinder for the cement mills, reducing the size of the particles before they are fed into them.

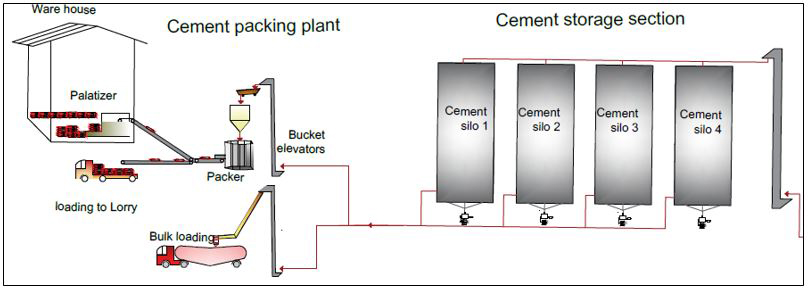

Cement is extracted from the silo and fed to the rotary screen/vibration screen through air slides/screw conveyors and bucket elevators. The manufactured cement is sent out from silos either through bulk tankers or cement bags. The bags are packed by two packers, and there is a palletizer warehouse where the bags are arranged on pallets to handle high demand. The cement bags weigh 50 kg each, and the packing process can dispatch cement at a rate of 40 bags per minute.

The cement manufacturing process is divided into two types: wet process and dry process, with the dry process being the most commonly used method worldwide. The Palavi process operation follows the dry process and was established in 1969 as a state-owned cement manufacturing cooperation.

Figure 02: process flow of the cement manufacturing process – palavi operation